In today’s rapidly evolving manufacturing landscape, automation is no longer a luxury—it’s essential. Additive manufacturing (AM) is no exception.

As the co-founder of 3D People, a subcontract AM service bureau, I’ve witnessed firsthand how automation has enhanced both operational efficiency and customer satisfaction. Integrating automation into our workflows has not only sped up processes but also delivered consistent, high-quality results to our clients.

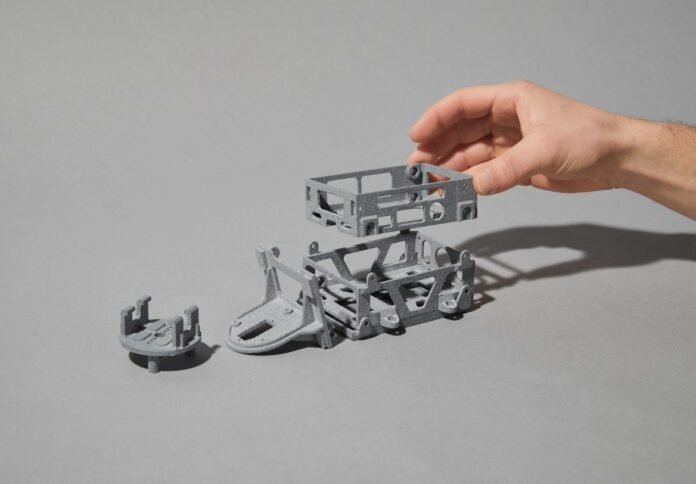

Automation in AM goes far beyond just robotic arms on production lines. It extends from the front-end service delivery—quoting, ordering, file preparation, and production management—through to post-processing, finishing, and the logistics of distribution. By optimizing these stages, automation ensures faster lead times, more consistent parts, and an improved overall customer experience.

In this article, I’ll explore how automation drives operational efficiency in AM services, the benefits it provides to customers, and why it’s crucial for the future of this industry.

Article by Felix Manley, Co-founder, 3D People

Why Automation Matters in AM

One common misconception about AM is that it’s inherently fast. While 3D printing does reduce time-to-part compared to traditional manufacturing, many manual steps can still slow the process down. This is where automation plays a vital role, eliminating bottlenecks.

For AM service providers, automation at the front-end—specifically in quoting, file handling, and order management—has transformative effects. For customers, this means faster responses, greater accuracy, and a smoother experience.

Automation streamlines quoting, file preparation, and production management, leading to reduced lead times, improved quality, and more reliable results for customers. Each of these areas provides unique advantages:

Automated Quoting Systems

Gone are the days of waiting for a sales rep to get back from a lunch break. Modern automated quoting systems can provide instant or near-instant pricing based on uploaded 3D files. At 3D People, we’ve invested heavily in our proprietary online quoting platform to offer customers rapid, accurate pricing.

With automated quoting, customers benefit from quicker decision-making. Instant quotes allow them to proceed with orders without unnecessary delays. They also receive accurate pricing, as automation reduces human error and ensures consistent pricing across different projects.

Transparency is another key benefit. Customers can see the cost breakdown and understand how factors like materials, finishes, and quantities affect the final price. This streamlined process accelerates the transition from idea to production-ready parts, far quicker than traditional methods.

File Handling and Preparation

File preparation is a critical step in AM. Ensuring a 3D file is printable, error-free, and optimized for the chosen technology and material can be time-consuming if done manually. Now, automation tools can automatically analyze and repair files, flagging potential issues early. At 3D People, we use these tools for tasks like thin wall checks and part orientation optimization.

For customers, this automation means fewer errors. Automated file checks catch issues early, reducing the risk of failed prints and speeding up workflows. It also ensures consistent part quality across orders, as every file is prepared to the same high standard.

Production Management and Workflow Automation

Once an order is placed and files are ready, the next challenge is managing production. In a busy AM service bureau, tracking multiple orders, machines, materials, and deadlines can quickly become a logistical nightmare without automation.

Workflow automation tools help manage this complexity by scheduling print jobs based on machine availability, prioritizing urgent orders, and tracking part progress throughout the production process. Automated scheduling ensures smooth operations, leading to reliable lead times and timely deliveries for customers.

At 3D People, we often need to group hundreds of customer jobs into one print run, then use software automation to organize them back into their respective orders. Without automation, this would be incredibly time-consuming.

Customers benefit from automated order tracking. Real-time updates reduce the need for manual follow-ups, offering a more transparent experience. Workflow automation also enables larger orders to be handled efficiently, ensuring scalability as demand grows.

Post-Processing Automation: The Final Step

While much of the focus in AM automation is on front-end processes, post-processing is another area where automation can provide significant benefits. Techniques like vapour smoothing, vibro-polishing, and dyeing can all be automated to some degree, ensuring consistent results across batches. Though high levels of automation in post-processing are still rare, this is an area of active focus.

For 3D People, automated post-processing is crucial. It ensures consistent quality across every part in a batch, meeting customer expectations. It also reduces costs by streamlining labor-intensive processes. Rather than automating the loading and unloading of parts, the focus is on automating the finishing process itself.

Additionally, automation speeds up post-processing workflows, leading to faster delivery times and shorter overall lead times.

Enhancing the Customer Experience: Faster, Smoother, Better

Ultimately, automation in AM is about improving the customer experience. When clients approach us with a project, they want to know three things: how much it will cost, how long it will take, and whether the parts will meet their expectations.

By automating key processes, we can deliver faster responses, more reliable lead times, and higher-quality parts. Customers experience shorter waiting times, as instant quotes and faster file handling reduce delays. Automation also boosts customer confidence, as automated checks and consistent processes ensure parts are correct the first time, eliminating the need for reprints or adjustments.

Why Automation is the Future of AM

As the demand for 3D-printed parts continues to grow, automation is an indispensable tool for service providers. Manual processes simply cannot scale to meet the needs of an ever-growing, fast-moving industry.

For 3D People, automation is about more than improving efficiency. It’s about delivering better service to our customers. It ensures that every part we produce is of the highest quality, delivered on time, and at a competitive price.

However, automation doesn’t mean eliminating the human element. At the core of every automated process is a team of experts ensuring the technology is used effectively. It’s the combination of human expertise and automated processes that sets us apart from other service providers.

If you’re looking for fast, reliable, and high-quality 3D printing services, 3D People is ready to help. Through automation, we can take your project from concept to completion faster than ever before.

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat