Ordering Code for 4WE6D7X/HG24N9K4

| Position | Code | Description |

|---|

| 01 | WE | Directional valve |

| 02 | 6 | Size 6 |

| 03 | 7X | Component series 70…79 (unchanged installation and connection dimensions) |

| 04 | / | Symbols e.g., D, E, etc.; possible design see page 3 |

| 05 | H | Standard solenoid, wet-pin |

| 06 | G24 | Direct voltage 24V |

| 07 | N9 | With concealed manual override |

| 08 | / | Further details in the plain text |

| 09 | * | Preferred types and standard units are contained in the EPS (standard price list) |

Additional Options

- Spring Return

- With spring return → no code

- Without spring return with detent → OF (only for symbol D)

- Electrical Connection

- K4: Without mating connector, with connector DIN EN 175301-803

- C4Z: Without mating connector, with AMP Junior-Timer

- Seal Material

- No code: NBR seals (other seals upon request, ensure compatibility with hydraulic fluid used)

(For applications outside these parameters, please consult us!)

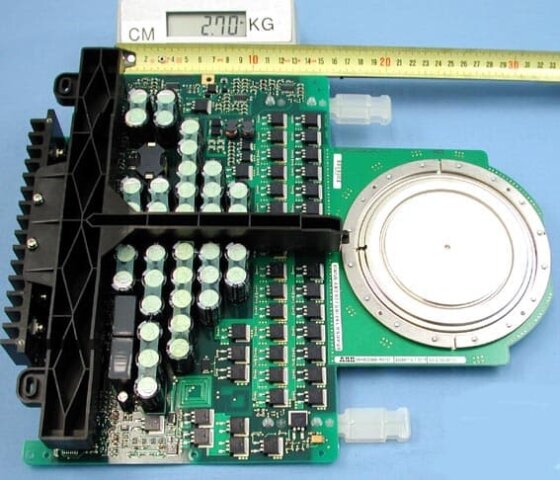

- Weight

- Valve with 1 solenoid: kg Approx. 1.25

- Valve with 2 solenoids: kg Approx. 1.6

- Installation position: –

- Ambient temperature range: °C -30… +50

- Maximum operating pressure

- Port A, B, P: bar 315

- Port T: bar 160 With symbols A and B, port T must be used as leakage port if the operating pressure exceeds the permissible tank pressure.

- Maximum flow: l/min 60

- Hydraulic fluid: See table below

- Hydraulic fluid temperature range: °C -30… +80

- Viscosity range: mm²/s 2.8… 500

- Maximum permitted degree of contamination of the hydraulic fluid – cleanliness class according to ISO 4406 (c): Class 20/18/15

| Classification | Suitable sealing materials | Standards |

|---|

| Mineral oils | | |

| – insoluble in water: HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 |

| – soluble in water: HETG | NBR, FKM | VDMA 24568 |

| Bio – degradable | | |

| – water – free: HEES | FKM | VDMA 24568 |

| – containing water: HEPG | FKM | VDMA 24568 |

| Flame – resistant | | |

| – water – free: HF DU, HF DR | FKM | ISO 12922 |

| – containing water: HFC (Fuchs Hydrotherm 46M, Petrotefer Ultra Safe 620) | NBR | ISO 12922 |

- For more information and data on the use of other hydraulic fluids refer to data sheet 90220 or contact us!

- There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)

- The flash point of the hydraulic fluid must be 40 K higher than the maximum solenoid surface temperature.

- Maximum pressure differential per control edge 50 bar

- Pressure pre – loading at the tank port > 20 % of the pressure differential, otherwise increased cavitation

- Life cycle as compared to operation with mineral oil HLP 50 to 100 %

When using bio – degradable hydraulic fluids that are simultaneously zinc – solving, zinc may accumulate in the fluid (per pole tube 700 mg zinc).

- Only actuate the manual override using a rounded tool (Ø3+¹ mm) or special tool (separate order, material no. R900024943!)

- Actuation of the manual override only up to a tank pressure of approx. 50 bar.

- When the manual override is blocked, the operation of the solenoid must be prevented!

- Actuation of the solenoids must be prevented!

- The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and at the same time increases the life cycle of the components. For the selection of filters see www.boschrexroth.com/filter

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat