Overview

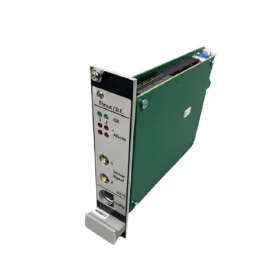

The Emerson A6210 Monitor is a high-performance dual-channel monitoring solution designed for thrust position, differential expansion, and rod position within the AMS 6500 Machinery Health Monitor system. It ensures accurate monitoring, rapid fault detection, and reliable machinery protection, making it an essential tool for turbomachinery, reciprocating compressors, and critical rotating equipment.

With API 670 & API 618 compliance, hot-swappable design, and seamless integration into Emerson’s DeltaV and Ovation process automation systems, the A6210 simplifies predictive maintenance and improves operational efficiency.

Key Features & Benefits

Comprehensive Machinery Protection

- Thrust Position Monitoring: Detects axial shaft movement to prevent rotor-to-case contact.

- Differential Expansion Measurement: Monitors thermal expansion differences between rotor and casing.

- Rod Position Monitoring: Identifies rider band wear in reciprocating compressors, preventing piston-cylinder contact.

High-Speed Fault Detection

- Detects small axial movements within 40 milliseconds, minimizing damage risks.

- Redundant sensors & voting logic enhance reliability.

- Built-in thrust bearing temperature monitoring for early fault diagnosis.

Advanced Data Acquisition & Outputs

- Two independent eddy current inputs, fully galvanically isolated.

- Buffered & proportional outputs (0-10 V, 0/4-20 mA) for seamless system integration.

- Built-in software linearization simplifies sensor adjustments post-installation.

Seamless System Integration & Configuration

- Hot-configurable measurement modes enable real-time monitoring.

- Preconfigured DeltaV & Ovation templates, reducing commissioning time.

- RS-232 interface for easy parameter adjustment and status monitoring.

Rugged & Reliable Design

- DIN 41494 PCB format, optimized for 19-inch rack mounting.

- IP-rated protection, ensuring durability in industrial environments.

- Low power consumption, using only 6W at 24V DC.

Technical Specifications

Transducer Inputs

- Number of Inputs: Two independent eddy current inputs

- Input Type: Differential, compatible with Emerson 6422, 6423, 6424, 6425 sensors

- Input Resistance: >100 kΩ

- Input Voltage Range: 0 to -22 VDC

- Measuring Frequency Range: 0 – 8 Hz (10 Hz, -3 dB)

Power Supply & Consumption

- Supply Voltage: -26.7 VDC (galvanically separated, open/short circuit proof)

- Available Current: Nominal 20 mA, max 35 mA

- Power Consumption: Max. 6W, 250 mA at 24 VDC

Output Signals

- Front Panel Buffered Outputs: Identical to transducer inputs (-1 to -24 V)

- Current Mode Outputs: 0/4-20 mA proportional to measured value (load <500 Ω)

- DC Voltage Outputs: 0 – 10 VDC proportional to shaft position (gap)

- Accuracy: ±1% of full scale

Alarm Setpoints & Safety Features

- Adjustable Alert & Danger Setpoints: 5-100% of full scale

- Self-Checking Diagnostics: Monitors power supply, sensor, cable, temperature, and module status

- LED Indicators:

- Green LEDs for channel status (OK)

- Red LEDs for alarm status (Alert & Danger)

Environmental & Mechanical Properties

- Operating Temperature: 0° to 65°C (32° to 149°F)

- Storage Temperature: -30° to 85°C (-22° to 185°F)

- Humidity: 5-95% relative, non-condensing

- Shock Resistance: IEC 68-2-29 (98 m/s² peak, 16 ms)

- Vibration Resistance: IEC 68-2-6 (0.15 mm, 10-55 Hz)

Dimensions & Space Requirements

- PCB/EURO Card Format: DIN 41494 (100 x 160mm | 3.937 x 6.300in)

- Width: 30.0mm (1.181in) (6 TE)

- Height: 128.4mm (5.055in) (3 HE)

- Length: 160.0mm (6.300in)

- Net Weight: Approx. 320g (0.705lbs)

- Gross Weight: Approx. 450g (0.992lbs), including standard packing

- Packing Volume: Approx. 2.5dm³ (0.08ft³)

- Space Requirements: 1 slot

- Rack Capacity: 14 modules per 19-inch rack

Ordering Information

| Model Number | Description |

|---|---|

| A6210 | Dual-channel Thrust, Differential Expansion, and Rod Drop Monitor |

Related Products – Protection Cards for AMS 6500 Classic Systems

| Model Number | Description |

|---|---|

| A6740-10 | 16-Channel Output Relay Module |

| A6740-12 | 16-Channel Output Relay Module |

| A6125 | Case Piezoelectric Vibration Monitor |

| A6120 | Case Seismic Vibration Monitor |

| A6824-R | ModBus and Rack Interface, 4TE |

| A6824 | ModBus and Rack Interface, 6TE |

| A6620 | Process Input Monitor |

| A6140 | Shaft Absolute Vibration Monitor |

| A6220 | Shaft Eccentricity Monitor |

| A6110 | Shaft Relative Vibration Monitor |

| A6312 | Speed and Key Monitor |

| A6312-8 | Speed and Key Monitor |

| A6630 | Temperature Monitor |

| A6210 | Thrust Position, Differential Expansion, and Rod Position Monitor |

| A6410 | Valve and Case Expansion Monitor |

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat