Overview

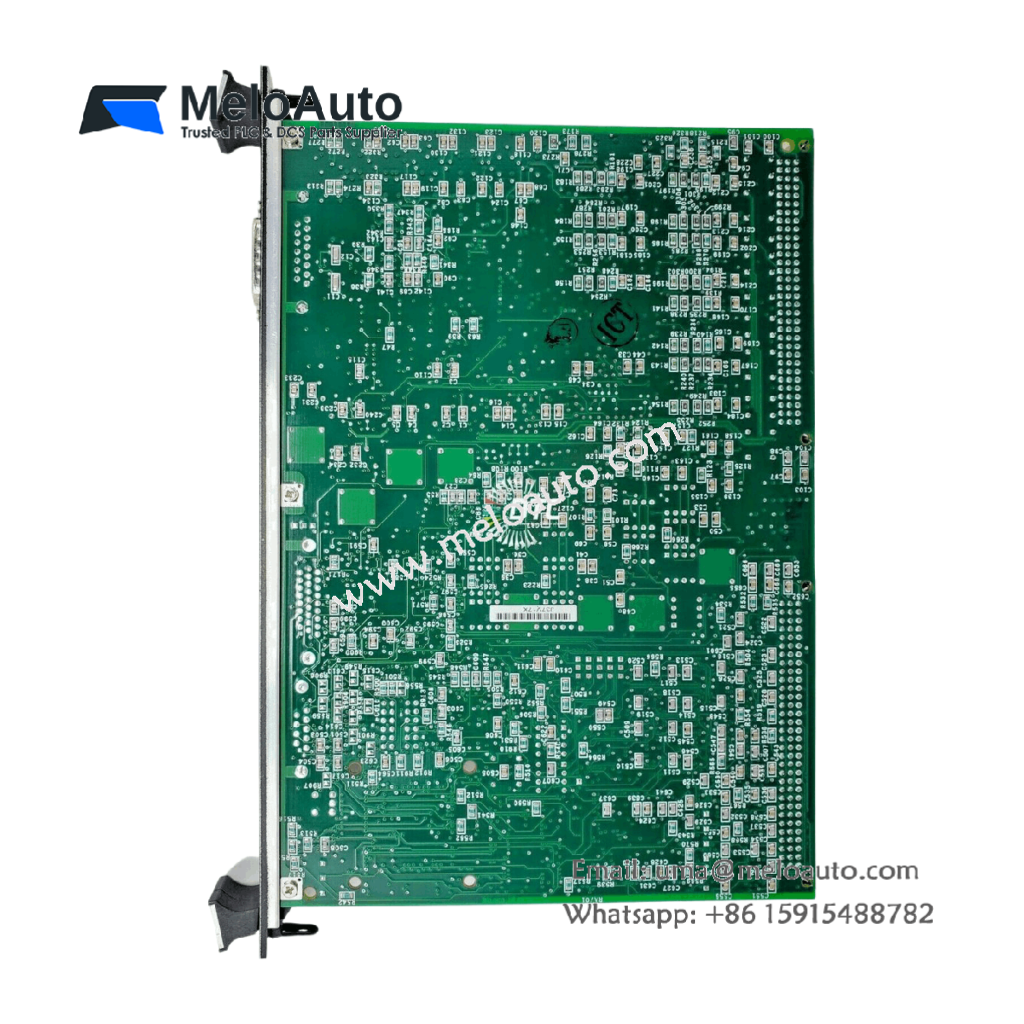

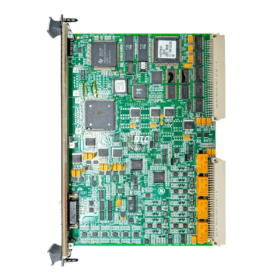

The GE IS200VSVOH1BDC is a servo control card designed for the Mark VI Turbine Control System, part of GE’s renowned Speedtronic product family. It provides precise control and monitoring for servo valve interface applications, supporting both pulse rate inputs and servo loop feedback. This board is widely used in steam, gas, and wind turbine systems.

Key Features

- Supports 2 to 3 coil servos

- Compatible with LVDT/LVDR feedback sensors

- Bi-directional current outputs

- Handles pulse rate inputs (2 Hz – 14 kHz)

- Designed for servo valve interface I/O applications

- Three onboard LEDs: Run, Fail, Status

- Suitable for TMR (Triple Modular Redundant) systems

- Interfaces with active and passive speed sensors

- Works with Backup Protection Modules for extended input support

Hardware and Revisions

- Product Code: IS200VSVOH1BDC

- Functional Acronym: VSVO

- Revision Levels:

- B: Functional upgrade

- D: Secondary functional revision

- C: Artwork/layout revision

- Mounting: Standard GE Mark VI rack

- System Integration: Works with Speedtronic Mark VI I/O and protection modules

- Documentation: Refer to GEH-6421C and GER-4193A system guides

Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | GE Industrial Systems |

| Series | Mark VI IS200 |

| Functional Description | Servo Control Card |

| Input Type | Pulse Rate / Servo Valve I/O |

| Pulse Input Frequency Range | 2 Hz to 14,000 Hz |

| Supported Servo Coils | 2 or 3 coils (3 recommended for TMR) |

| Feedback Types | LVDT / LVDR / Pulse Rate |

| Speed Sensor Types | Active and Passive |

| Cold Excitation Requirement | AC Excitation for LVDTs |

| Channel Configuration | 4 Servo Channels |

| Feedback Sensor Redundancy | Median, High, or Low select via software |

| LEDs | RUN, FAIL, STATUS |

Applications

- Steam turbine control

- Gas turbine regulation

- Wind turbine servo systems

- Flow divider feedback loops

- High-reliability TMR-based installations

Why Choose This Module

As a legacy GE Speedtronic Mark VI component, the IS200VSVOH1BDC offers proven reliability in demanding turbine control systems. It enables accurate, stable servo control with support for sensor redundancy and advanced diagnostics.

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat