Key Benefits

- Low-Cost, Scalable Options: Event reports, waveform capture, reclosure functionality

- Reduced Troubleshooting & Maintenance Costs: Event reports and waveform capture features streamline diagnostic processes.

- Design Flexibility: User-friendly programming logic for easy customization.

- Asset Monitoring: Monitors breaker health and failure.

- Information Access: Modbus RTU communication for remote monitoring and control.

- Configurable Logic and Parameters: Customizable curves, I/O settings, and LEDs.

- Flash Memory for Field Upgrades: Allows for easy system updates.

- Two Settings Groups: Dual configuration options for different operating scenarios.

- Password Protection: Ensures secure local operation.

- Automatic Fault Information Display: Displays last fault data automatically.

- AC/DC Power Supply: Flexible power options for versatile installations.

- Improved User Interface: Enhanced ease of operation.

- Communication Access: Can be accessed through the front panel or remote communication links.

- EnerVista™ Compatibility: Simplifies system setup and monitoring.

- Isolated Front RS232 Serial Port: Ensures secure and isolated data transmission.

Applications

- Primary Feeder Protection: Ideal for use on distribution networks.

- Backup/Auxiliary Protection: Provides protection for transformers, generators, and motors.

Features

Protection and Control

- Phase and Ground TOC & IOC: Time Overcurrent and Instantaneous Overcurrent protection for both phase and ground faults.

- Thermal Image Protection: Monitors the thermal behavior of the feeder.

- IAC Time-Current Curves: Protection curves tailored to industrial and utility applications.

- Circuit Breaker Control: Includes open and close controls for circuit breakers.

- Four-Shot Autorecloser: Automatically restores the feeder after fault clearing.

- Cold Load Pickup: Helps with re-energization after a feeder has been out of service.

- Configurable Breaker Failure: Offers adjustable settings for breaker failure to open.

- Configurable I/O: Customizable I/O settings for flexible integration into control systems.

Monitoring and Metering

- 32-Event Recorder: Records the latest fault events for analysis.

- Oscillography: Captures analog and digital oscillography for detailed fault analysis.

- KI2 Counter for Breaker Maintenance: Tracks breaker operations for maintenance scheduling.

- Per-Phase Current Metering: Provides individual phase current monitoring.

- Last Five Trips Monitoring: Displays data from the last five trips for troubleshooting.

User Interfaces

- EnerVista™ Software: Industry-leading software for device configuration and monitoring.

- LCD Display: 2×16 character display for real-time data and settings.

- LED Indicators: Six LED indicators, four of which are configurable in function and color.

- Communication Ports: RS232 (front) and RS485 (rear) for local and remote communication.

- Multiple Protocols: ModBus RTU, IEC 60870-5-103 for diverse control system integration.

Technical Specifications

Protection

Phase / Ground Time Overcurrent

- Pickup Level: 0.1 – 2.4 times In (rated current) in steps of 0.01 x In.

- Curve Shapes: IEC (A/B/C), ANSI Inverse, IAC Inverse.

- Timing: Adjustable from 0.00 to 600.00 seconds.

- Accuracy: ±1% at rated current, ±3% in complete range.

Phase / Ground Instantaneous Overcurrent

- Pickup Level: 0.1 to 30 times In, with steps of 0.1 x In.

- Operate Time: 20 to 30 ms for I > 1.5 x Actual Pickup.

- Timing Accuracy: ±3% for I > 1.5 x Actual Pickup.

Thermal Image Element

- Pickup Level: 0.1 to 2.4 times In.

- Timing Accuracy: 5% for operate times greater than 2 seconds.

Communications

- Local Communication: 2×16 LCD Display, 5-button keypad.

- Remote Communication: ModBus RTU, Baud rate: 300 to 19200 bps.

- Ports: RS232 (front), RS485 or IEC 60870-5-103 (rear).

Metering

- Accuracy: ±1% at In, ±3% in the full range.

- Current: Fundamental current measurement for precise monitoring.

Monitoring

- Oscillography: Records 1 x 24 cycles with a sampling rate of 8 samples per power frequency cycle.

- Event Recorder: 32 events with time-tagging to 1 ms.

Inputs and Outputs

AC Current Inputs

- Rated Current: 1A or 5A, depending on the model.

- Relay Burden: < 0.2 VA @ In = 5A secondary.

- Current Withstand: 4 x In continuously, 100 x In for 1 second.

Digital Inputs

- Voltage Level: 300 Vdc max for HI power supply; 75 Vdc max for LO power supply.

- Recognition Time: < 4 ms.

Outputs

- Relay Configuration: 6 Electro-Mechanical Form C.

- Relay Material: Silver alloy suited for inductive loads.

- Contact Ratings: 30 A make and carry, 10 A continuous, breaking 4000 VA.

Power Supply

- Low Range: 24 to 48 Vdc, with a backup time of more than 1 week.

- High Range: 110 to 250 Vdc or 110 to 230 Vac.

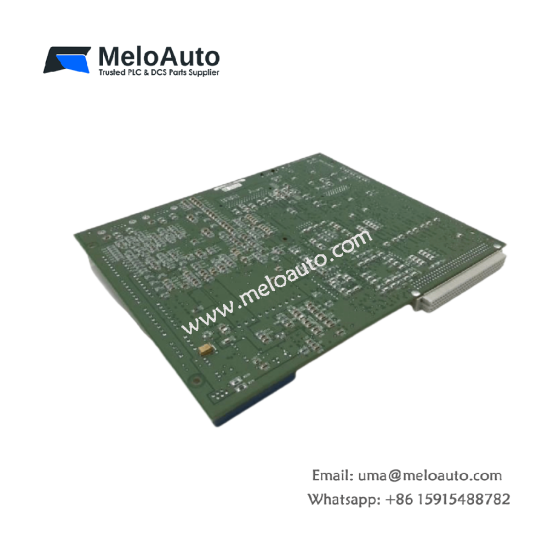

Mechanical Characteristics

- Package: 1/4 19” rack, 4 units high.

- Protection: IP52 (according to IEC 529).

Environmental Specifications

- Temperature: Operation: -20ºC to +60ºC; Storage: -40ºC to +80ºC.

- Humidity: Up to 95% without condensation.

- Pollution Degree: 2.

Approvals

- Certifications: Conforms to 89/336/CEE and 73/23/CEE, UL508, ISO9001.

Ordering Information

MIF II-P-I-1-1-E-1-0-HI-0-0 (MIFIIPI11E10HI00)

- Base Unit: MIF

- Application: P (3 Phase + Ground relay)

- Curves: I (IEC Curves)

- Phase Ranges: 1 Phase CT In = 1A (0.1-2.4 A)

- Ground Range: 1 Ground CT = 1 A (0.1-2.4 In)

- Language: E (English)

- Options: 1 (Configurable I/O/LEDs, event recording, oscillography)

- Recloser Option: 0 (Without Recloser)

- Power Supply: HI (110-250 Vdc)

- Protocol: 0 (Standard Model – Modbus RTU)

- Conformal Coating: 0 (Without Harsh Environment Conformal Coating)

MeloAuto-Trusted PLC & DCS Parts Supplier

MeloAuto-Trusted PLC & DCS Parts Supplier

WeChat

Scan the QR Code with wechat